The horrible accident of the Coromandel Express, also involving the Yeshwantpur-Howrah Express and a goods train has placed the Indian Railways under a lot of scrutiny. Given that significant part of the Indian Railways infrastructure was constructed during the British era and therefore of ancient antiquity, it makes the regular inspection and maintenance of the tracks and other ancillaries extremely critical for safety and security.

In this respect, we decided to make a series of reviews on the maintenance of assets at Indian Railways. In this, our primary source is the “Report of the Comptroller and Auditor General of India for the year ended March 2021: Derailment in Indian Railways.”

Disclaimer: This article does not make any attempt to investigate causes of the tragic accident at Balasore last week. This is a review of the adherence on ground to the prescribed practices for safety and security by the Ministry of Railways. It covers the period of 4 years from April 2017 – March 2021.

Monitoring of tracks by track recording cars:

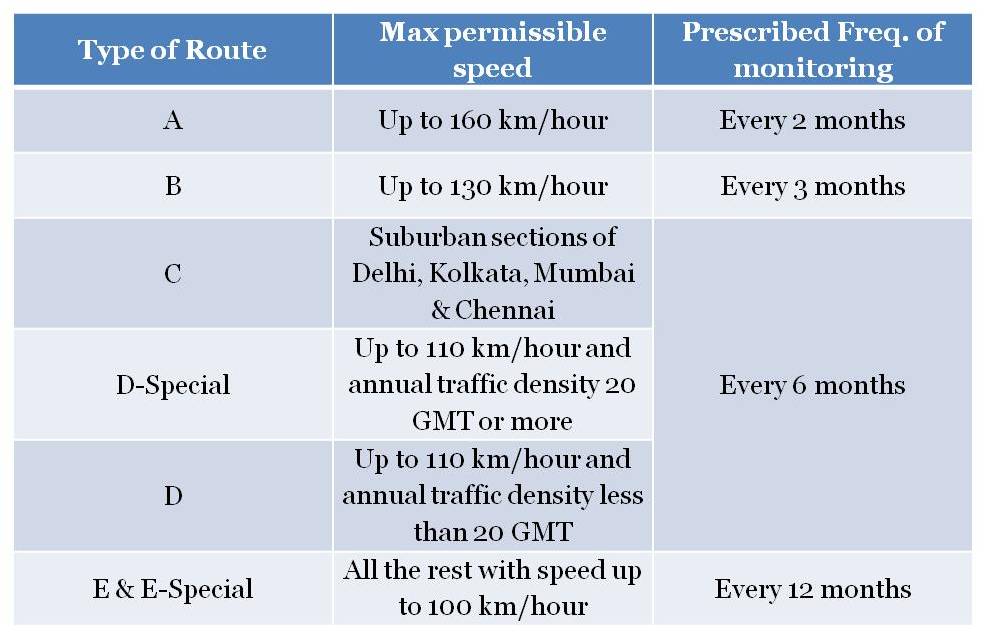

The permanent way staff responsible for track maintenance carries out regular periodic inspections to assess the health of the tracks: structurally and geometrically. The CAG Audit report classifies broad gauge lines into 6 groups basis maximum permissible speed. The target frequency of monitoring for each group as prescribed by Indian Railways is also given in the below table:

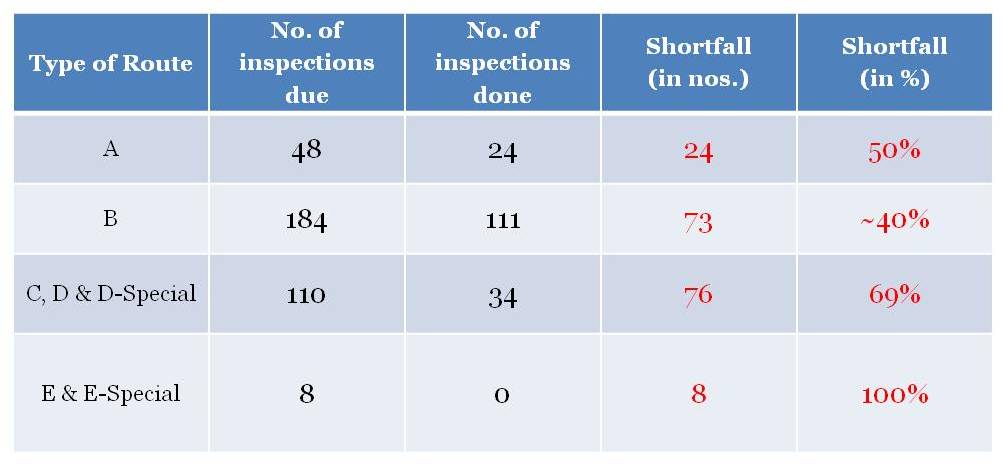

The no. of inspections due, no. of inspections done and shortfall (in nos. & %) is given below for the period 2017 – 2021:

As can be seen from the above table, the scheduled inspections were left pending by anywhere between 40 & 100% for the review period. It is worth pointing out that pending inspection by track monitoring cars poses significant danger to safety of train movement.

In Feb, 2019, the Seemanchal Express had derailed in Vaishali, Bihar. Six people were killed and 30+ were injured. The accident was caused by a fracture in the track. The inspection on the particular section where the derailment occurred was overdue for four months.

Outsourcing of Maintenance Personnel

Maintenance of tracks in Indian Railways is to be taken care of by internal personnel resources, outsourced manpower solutions or a combination of both. In case where internal resources are short in supply, the concerned authorities are expected to close the gap through outsourcing.

The CAG Audit though finds some glaring omissions:

For the review period (2017-21), there was 9-36% vacant posts in the Civil Engineering department across different railway zones

In selected divisions of East-Central Railway (ECR) under audit, there were 172 derailments in the concerned period. In 40 of these cases, a major cause of derailment was improper maintenance of tracks. The vacancies in civil engineering departments in ECR and also Western Railway (WR) was between 19 & 30%

In ECR, no outsourcing solution was resorted to. In WR, outsourcing was also done but fell short of the target by 23 & 29% in three out of four years of review

In Central Railway (CR), Northern Railway (NR), North-Western Railway (NWR) and South-Central Railway (SCR), % of vacancies ranged between 10 and 21%

In NWR & SCR, no outsourcing was done

In NR, no outsourcing was done in three out of four years. In the other year, 11 outsourcing was done against 154 vacancies

In three zones: North-Central (NCR), North-Frontier (NFR) and West-Central (WCR), % of vacancies in civil engineering department was 7%+. In none of these zones, any outsourcing was done

It is needless to point out that shortage of manpower is most likely to have a severe adverse effect on safety and security of rail traffic.

Mechanization of Maintenance Process of Tracks

Due to technological advancements in rails, sleepers, fastenings, points, crossings etc, manual maintenance of tracks has become more and more difficult. Mechanized automation has thus steadily gained in importance over the last 8 – 10 years.

The CAG Audit examined utilization of track maintenance machines in 12 selected railway zones out of 19. In these 12 zones, 517 machines were deployed, amounting to a total possible 7, 54,820 machine-days over the four review years. Out of these, machines remained idle in 1, 20,135 machine-days – amounting to 16%.

Under-utilization of track maintenance machines is a serious demonstration of inefficiency in track maintenance process.

Introduction of wider and heavier pre stressed concrete sleepers

Due to increasingly greater load on the tracks due to growth on freight traffic, Indian Railways has been looking to upgrade existing slender and lightweight sleepers to more load bearing ones. Towards that end, Research Design & Standard Organization (RDSO) developed a new wider and heavier stress bearing sleeper called RT – 8527 which was approved by Railway Board (RB) in July, 2018 for use from 2019-20 onwards.

The directive from RB specified the following:

If adjoining patches are likely to be renewed for five years, it was advised to use RT-8527 sleepers except for very short patches (< 500 meters)

If “Through Track Renewal” is to be carried out within next five years, it was advised to carry out “Complete Track Renewal” using RT-8527 sleepers and 60 kg rails

For track renewal of sanctioned patches where continuous length is less than 2 kms, RB allowed procurement of ordinary line sleepers

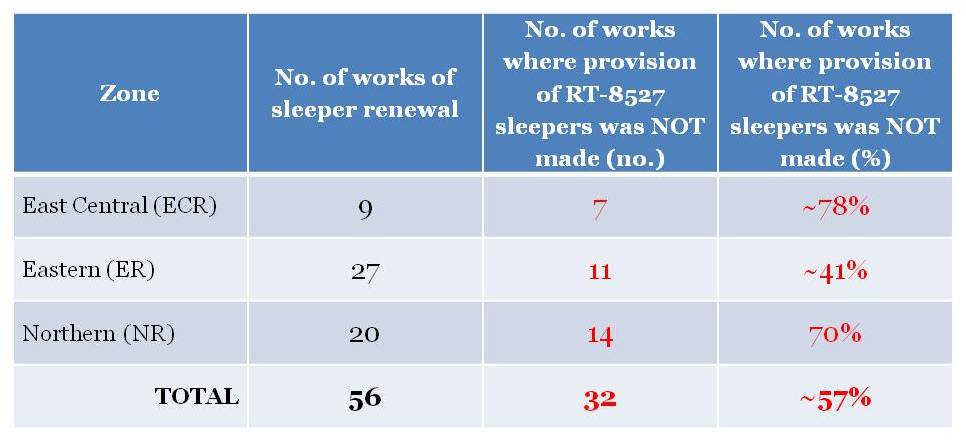

CAG Audit regarding use of RT-8527 sleepers in sanctioned patches of > 2 kms in length from 2019-20 onwards revealed following findings:

The non-use of RT-8527 sleepers is a direct deviation from the directive issued by Railway Board and a serious compromise on safety.

NB: It is to be borne in mind that since adoption of RT-8527 sleepers was scheduled from 2019-20; this activity would have been adversely affected during the last year of the review cycle (2020-21) when the Covid-19 pandemic was raging. However, even bearing the same in mind, the level of deviation in ECR and ER is unacceptably high.

Alumino Thermit and Flash Butt Welding

The rail joint is a critical part of the track and hence its solidity and reliability becomes vital for safe operations. In Indian Railways, two types of processes are used for joint welding: Alumino Thermit (AT) and Flash Butt (FB). AT welding is a manual process, which uses molten iron to weld gap between rails. FB welding on the other hand involves an automated track-laying machine running a strong electrical current through the touching ends of two un-joined pieces of rail to form a strong bond. The AT welded joints are less reliable and more prone to fracture as compared to FB welds.

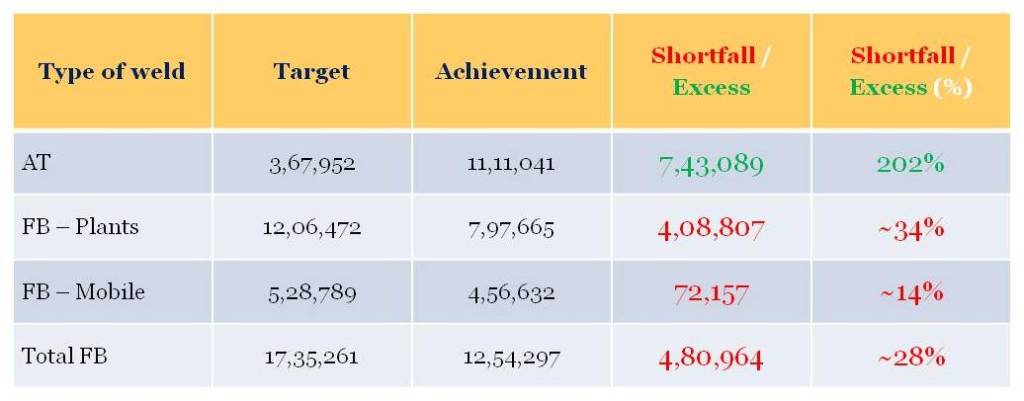

The Indian Railway Corporate Safety Plan of 2003-13 therefore emphasized on gradual reduction of AT welds and replacement by the more robust FB welds. Obviously, the FB welds are supposed to impart greater safety assurance to train movement. The CAG Audit naturally focuses on target achievement of FB welds. The results are below:

As can be observed from the above data, there is a nearly 30% deficit in targeted FB welding. On the other hand, a 200%+ overachievement is observed in carrying out of the less secure AT welding. This is a severe and serious breach of safety guidelines by the Corporate Safety Plan.

The audit further finds that across the surveyed railway zones, a total of 379 welding contracts were issued – out of them, only 14% (53) were FB contracts, rest all were AT contracts. In two of the zones, no FB contract was allotted.

Ultra Sonic Flaw Detection Testing (USFD):

Ultra Sonic Flaw Detection (USFD) testing is a most advanced methodology to ensure safety of tracks. The Indian Railways Permanent Way Manual prescribes the necessary frequency of USFD testing of rails and welds.

The CAG Audit finds the below results on adherence of USFD testing in different railway zones during the audit period (2017-21):

Northern Railway: 50% deficiency (rails)

NW Railway: 11% deficiency (rails)

SW Railway: 4 – 41% deficiency (rails)

SE Railways: 4 – 42% deficiency (welds)

Western Railway: 10 – 37% deficiency (welds)

NF Railway: 4 – 23% deficiency (welds)

East Coast Railway: Up to 100% deficiency (welds)

Timely USFD testing of tracks and welds is likely to help the maintenance team to identify potential vulnerable points in advance and therefore, undertake necessary measures to prevent the same from resulting in an accident.

Lack of adherence of prescribed frequency of USFD testing is hence a serious compromise with rail safety.

Conclusion

A summary of the above highlighted points makes it clear that during the review period (2017-21), there were gross misses and deviations in Indian Railways’ maintenance of tracks, welds, slippers etc. Such deviations and deficits pose tremendous risk to lives and property. Given the importance of the railways in movement of people and cargo across the country, it is imperative that the Railway Board take immediate cognizance of such deviations and urgent steps are undertaken to resolve the same in the shortest possible time.

(To be continued)